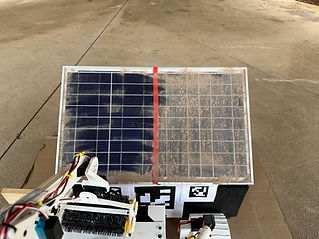

The Astraeus prototype was developed to demonstrate the feasibility of a semi-autonomous Martian rover capable of locating, cleaning, and maintaining solar panel surfaces using a custom robotic arm and AI-assisted navigation. Below is not only the finalized prototype of Astraeus (Fig. 1) but also our results from testing trials which demonstrate how each high-level requirement was addressed and validated through real-world testing.

.jpg)

Figure 1. Astraeus Prototype

Robotic Arm (Cleaning System) Engineering Requirements

High Level Requirement 1:

" Astraeus must utilize a variable speed cleaning brush with precise control over speed and pressure to effectively clean surfaces. "

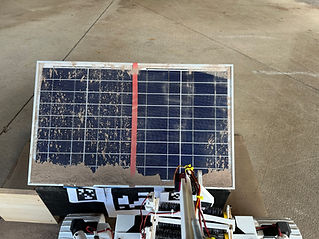

Astraeus fulfilled this requirement through the integration of a variable-speed motor-controlled brush mounted on a 5-axis robotic arm. During testing, the brush was able to adjust its speed and maintain consistent pressure across the solar panel surface, ensuring effective dust removal without damaging the panel. Control over brush speed was verified through onboard commands stored in the Maestro controller, and brush responsiveness was validated through multiple cleaning cycles. As shown below in Figures 2 and 3, the brush successfully removed MGS-1 dust from the panel sections one and two, demonstrating effective and controlled operation in simulated Martian conditions.

.jpg)

Figure 2. Panel Section 1 cleaned

.jpg)

Figure 3. Panel Section 2 cleaned

Medium Level Requirement 1:

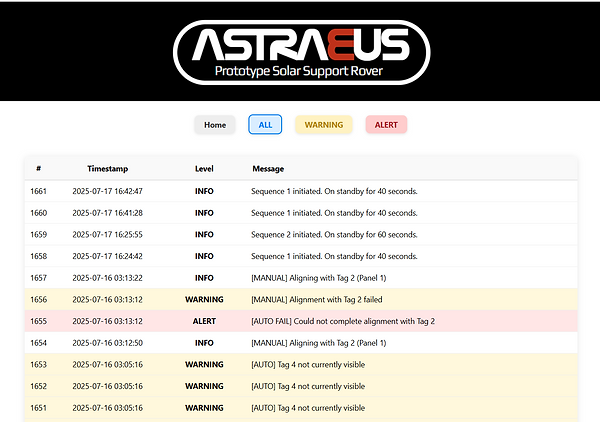

" Astraeus must document before and after cleaning the solar panel by logging the data for the user to analyze the performance of the rover. "

Astraeus fulfilled this requirement by using its onboard Raspberry Pi to host a local server that logs all key events into a database. The system records when panel alignment begins, when alignment is completed, and when cleaning starts on ether Panel 1 or Panel 2. This allows users to analyze performance metrics and track the rover’s cleaning activity across multiple test cycles. The structured logging system provides a reliable method for verifying successful operation and identifying trends or inconsistencies over time.

Figure 5. Data Log

Navigation Engineering Requirements

High Level Requirement 1:

" Astraeus must Autonomously determine its own path to solar panels while avoiding obstacles. "

High Level Requirement 2:

" Astraeus must detect larger obstacles up to 40cm without running into them without human intervention. "

High Level Requirement 3:

" Astraeus must recognize visual cues such as QR codes, distinct shapes, or colored markers to identify target zones. "

Medium Level Requirement 1:

" Astraeus must Return to the starting position without any human intervention. "

Astraeus successfully met all navigation engineering requirements by demonstrating full autonomous mobility, obstacle avoidance, visual marker recognition, and return-to-base functionality with integrated event logging.

To reach the solar panel, Astraeus used AprilTag 1 as its primary navigation target. The rover determined its path independently and monitored for obstacles in real time. It was able to detect objects up to 40 centimeters away and stop to avoid collisions without human intervention. Once AprilTag 2, the alignment marker, came into view, Astraeus locked onto it and aligned the robotic arm and cleaning mechanism with the panel surface to begin the cleaning sequence.

After completing the cleaning cycle, Astraeus backed away from the panel, performed a 180-degree turn, and navigated back to AprilTag 3, which marked its original starting position. This confirmed that the system could return to base without any manual input.

Throughout the entire process, Astraeus logged each event using a local server hosted on the onboard Raspberry Pi. Events included navigation start, obstacle detection, alignment with the panel, cleaning start and completion, and the return to the initial location. These logs provided a clear record of performance during each test.